Huahana

ʻO ka pulupulu kila kila a i ʻole ka uea conductive i loko no ka textiles hiki ke wela

Hōʻike huahana

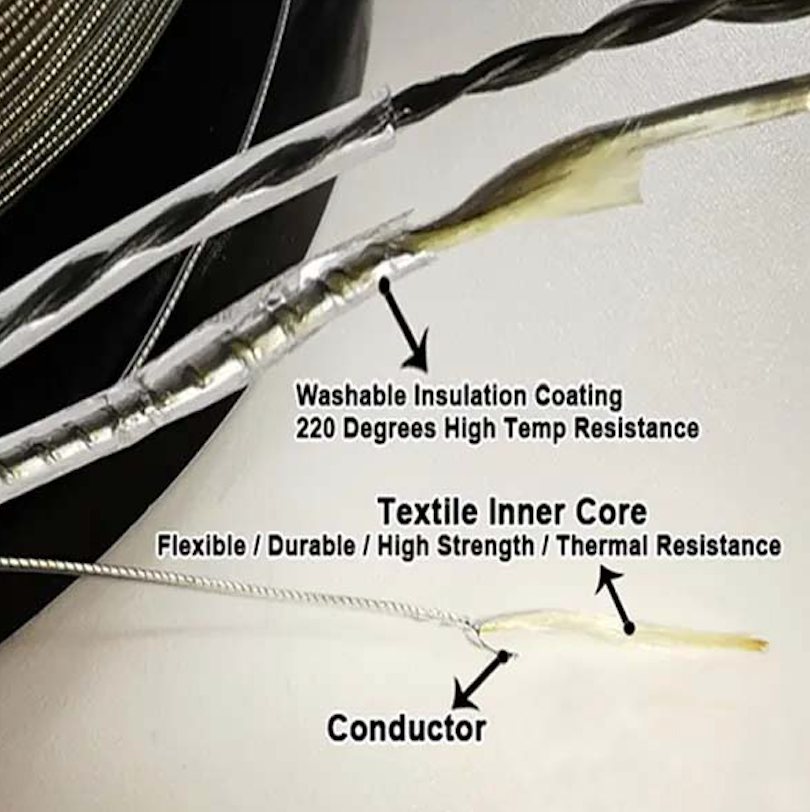

ʻO 1-Stainless steel fiber based pūpū kahi o ke anawaena o kēlā me kēia fiber he 12µ a i ʻole 14µ. ʻO ka nui o nā fibers maʻamau mai ka 200 a ʻoi aku ma mua o 1500 filaments. Hāʻawi kēia iā ʻoe i kahi lōʻihi i ʻoi aku ka maikaʻi ma ka papa. Ma muli o nā fiber maikaʻi i hoʻohana ʻia, ʻoi aku ka lahilahi o kēia mau kaula i ke anawaena holoʻokoʻa a no laila hiki ke maʻalahi i ka hana ʻana.

2-Ke uhi nei mākou i kahi ākea ākea o ka haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa ʻoi aku ka maikaʻi a me nā micro cable me nā ʻano paʻa a hiki ke hoʻololi ʻia, ʻoi aku kā mākou me ka textile core core micro cables hiki ke hōʻoia i ke kūpaʻa i kēlā me kēia mika āu e pono ai a hāʻawi iā ʻoe i ka maʻalahi i ka hoʻolālā akā hāʻawi mau i kahi ʻoi aku ka maikaʻi. flex-ola ma mua o typical Cu- uwea. Ma muli o ka mea i hoʻopaʻa ʻia i waho i hiki ke hoʻopaʻa ʻia, keleawe, keleawe a me nā mea ʻē aʻe, hiki iā mākou ke hana i ka conductive resistant ʻoi aku ka haʻahaʻa ma mua o 1 ohm / m micro cables e nā ʻano hoʻokahi a stranded e like me ka koi o ka mea kūʻai aku.

ʻO nā mea maikaʻi o nā uwea micro core i loko

Kū'ē kūlou

Ma muli o ke ʻano a me ka hui pū ʻana o nā mea, ʻoi aku ka maikaʻi o ke kūlou ʻana o ka uea.

ʻoluʻolu

Hoʻohana ka micro cables i ka foil metala lahilahi e like me ke alakaʻi, e ʻike i ka maʻalahi.

Maikaʻi Loa

Ma hope o ka extrusion ko mākou micro cable thinest hiki i 0.35mm.

Ka Ikaika Kiekie

Hoʻohana mākou i nā fibers Aramid / Liquid Crystal Polymer a me nā ʻenehana loea kiʻekiʻe.

Kiʻekiʻe Temp. Kūʻē

Hoʻohana mākou i ka aramid a i ʻole stanless steel fiber bundle filaments no nā fibers, ke kiʻekiʻe kiʻekiʻe ke kū kūʻē mai 230 degere a 580 degere no kāu koho.

ʻO ka hoʻopau ʻana a me ka uhi ʻana

I kou honua, he nui ka pono no ka lacquering kanaka o na filaments a i ole ka uhi extrusion holoʻokoʻa ma luna o ke kaula piha. Hiki iā mākou ke hana i kēlā, ʻo kā mākou extrusion maʻiʻo me FEP, PFA, PTFE, TPU etc.

KA HOAkaka o ka JACKET INSULATION

| Extrusion | TPE | FEP | MFA |

| Mlae elting | 205° C | 255° C | 250° C |

| CʻO ka hana mau Temperature | 165° C | 205° C | 225° C |

Nā Puʻupuʻu Fiber Steel

Nā Hana Hana Uila Uila Uila Loko

Hoʻokumu ʻia i ka mea hoʻomehana i hoʻopaʻa ʻia

ʻO nā puʻupuʻu kila kila i nā pae kūʻē like ʻole no kāu kuhikuhi.

| Anawaena (um) | Nā filaments | Ka ikaika (cN) | Kaumaha (g/m) | Elongation (%) | Hoʻokuʻu (Ohm/ m) |

| 8 | 1000F x 1 | 69 | 0.420 | 1.10 | 16 |

| 8 | 1000F x 2 | 108 | 0.850 | 1.10 | 8 |

| 12 | 100F x 1 | 24 | 0.110 | 1.10 | 59 |

| 12 | 100F x 2 | 41 | 0.190 | 1.10 | 38 |

| 12 | 100F x 3 | 69 | 0.280 | 1.10 | 22 |

| 12 | 257F x 1 | 59 | 0.260 | 1.10 | 27 |

| 12 | 275F x 2 | 75 | 0.540 | 1.10 | 14 |

| 12 | 275F x 3 | 125 | 0.780 | 1.10 | 9 |

| 12 | 275F x 4 | 130 | 1.050 | 1.10 | 7 |

| 12 | 275F x 5 | 160 | 1.300 | 1.10 | 5 |

| 12 | 275F x 6 | 180 | 1.500 | 1.10 | 4 |

| 12 | 1000F x 1 | 100 | 0.950 | 1.10 | 7 |

| 12 | 1000F x 2 | 340 | 1.900 | 1.10 | 4 |

| 14 | 90F x 2 | 46 | 0.190 | 1.10 | 44 |

| 14 | 90F x 1 | 25 | 0.110 | 1.10 |

Textile inner core conductive uea okoa kū'ē pae

| Lunahooponopono waho | Koko Loko Textile | Anawaena mm | ʻO ka hoʻokō ≤Ω/m |

| keleawe 0.08mm | 250D Poyester | 0.20±0.02 | 6.50 |

| keleawe 0.10mm | 250D Polyester | 0.23±0.02 | 3.90 |

| keleawe 0.05mm | 50D Kuraray | 0.10±0.02 | 12.30 |

| keleawe 0.1mm | 200D Dinama | 0.22±0.02 | 4.00 |

| keleawe 0.1mm | 250D Polyester | 1*2/0.28 | 2.00 |

| keleawe 0.1mm | 200D Kevlar | 0.22±0.02 | 4.00 |

| keleawe 0.05mm | 50D Polyester | 1*2/0.13 | 8.50 |

| keleawe 0.05mm | 70D Polyester | 0.11±0.02 | 12.50 |

| keleawe 0.55mm | 70D Polyester | 0.12±0.02 | 12.30 |

| keleawe 0.10mm | pulupulu 42S/2 | 0.27±0.03 | 4.20 |

| keleawe 0.09mm | 150D Polyester | 0.19±0.02 | 5.50 |

| keleawe 0.06mm | 150D Polyester | 0.19±0.02 | 12.50 |

| Tin Copper 0.085mm | 100D Kuraray | 0.17±0.02 | 5.00 |

| Kino keleawe 0.08mm | 130D Kevlar | 0.17±0.02 | 6.60 |

| Tin Copper 0.06mm | 130D Kevlar | 0.16±0.02 | 12.50 |

| Tin Copper 0.10mm | 250D Polyester | 0.23±0.02 | 4.00 |

| Tin Copper 0.06mm | 150D Polyester | 0.16±0.02 | 11.6 |

| Tin Copper 0.085mm | 200D Kevlar | 0.19±0.02 | 5.00 |

| Tin Copper 0.085mm | 150D Polyester | 0.19±0.02 | 6.00 |

| Kālā keleawe 0.10mm | 250D Polyester | 0.23±0.02 | 3.90 |